PRECISION WELDED TUBES

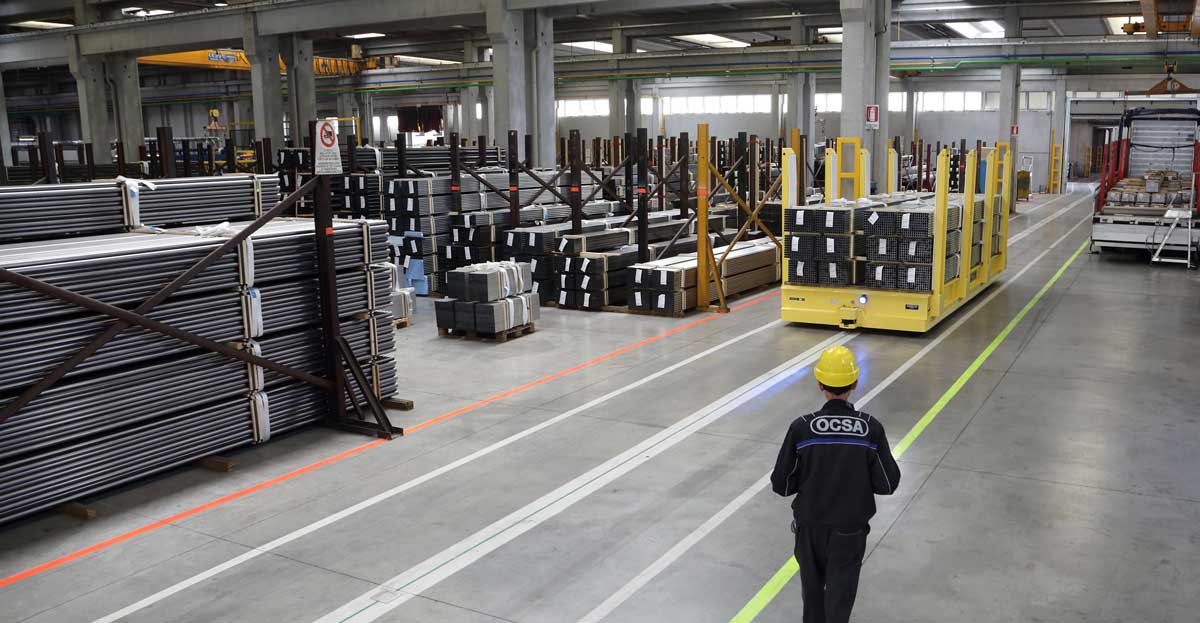

In our Crocetta del Montello (TV) plant we manufacture precision round and shaped electro-welded (HFI) tubes in compliance with the European EN 10305-3 and 10305-5 standards.

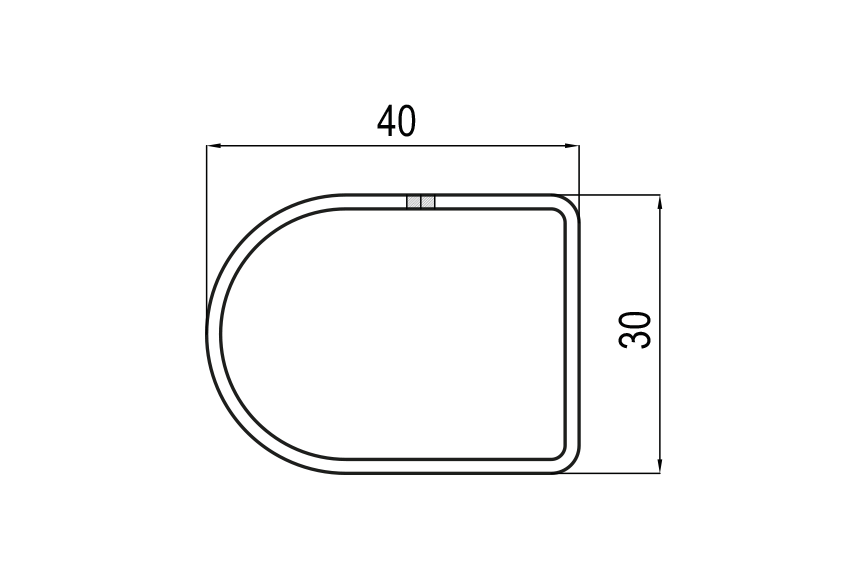

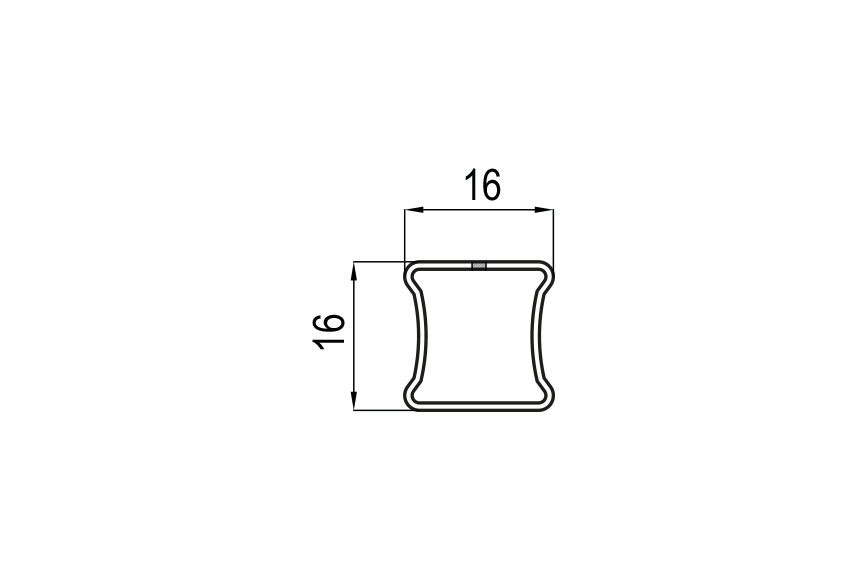

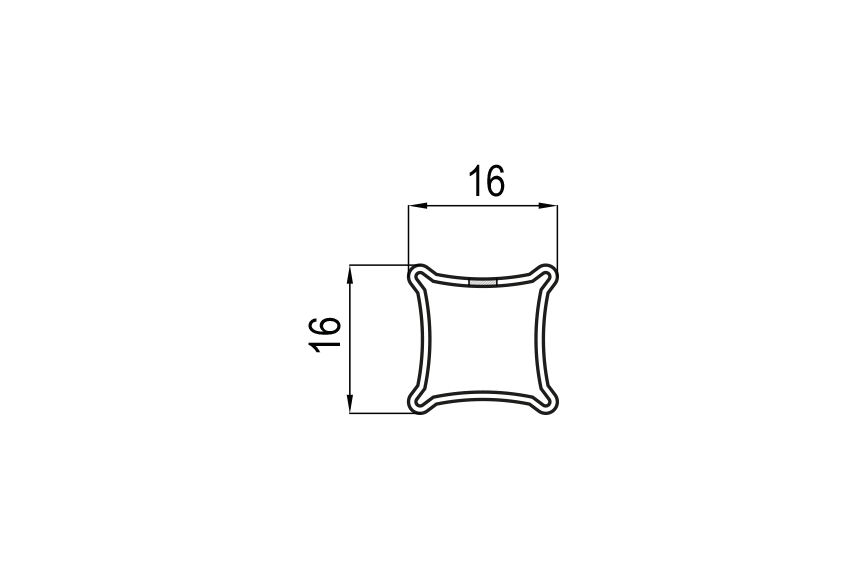

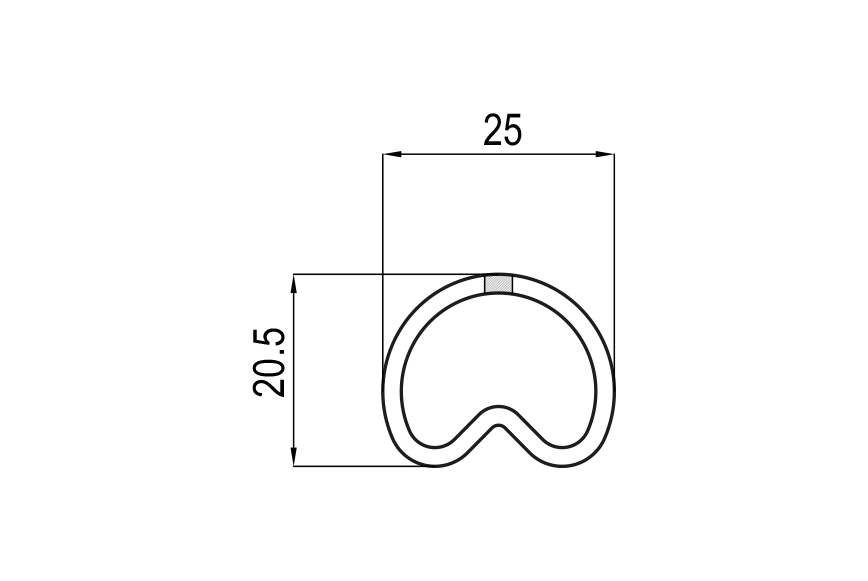

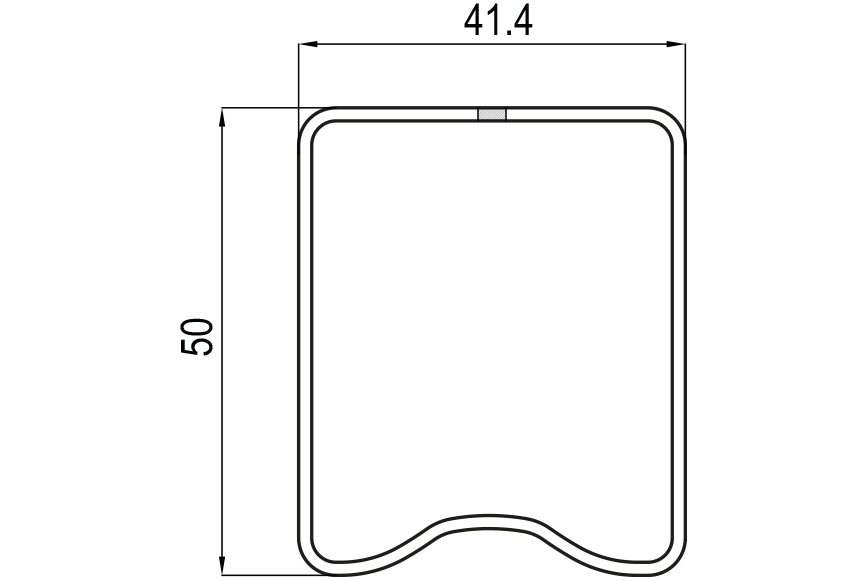

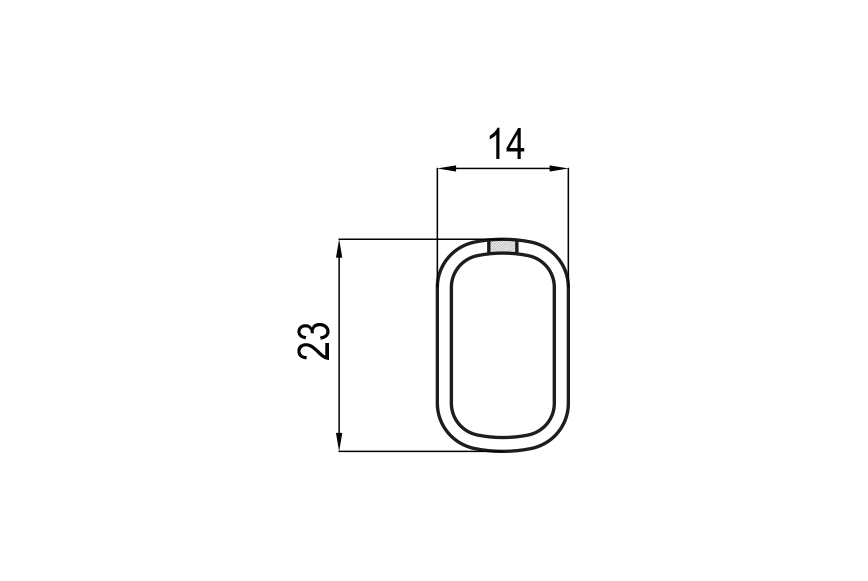

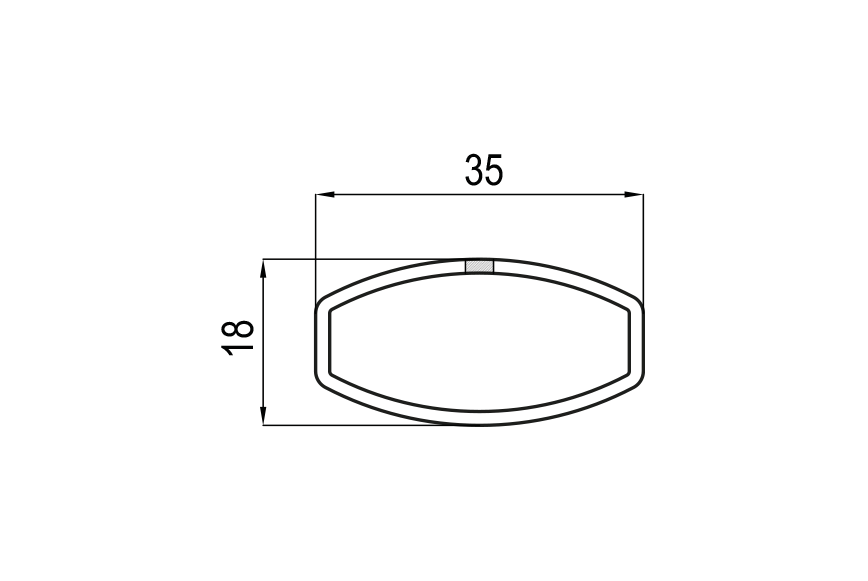

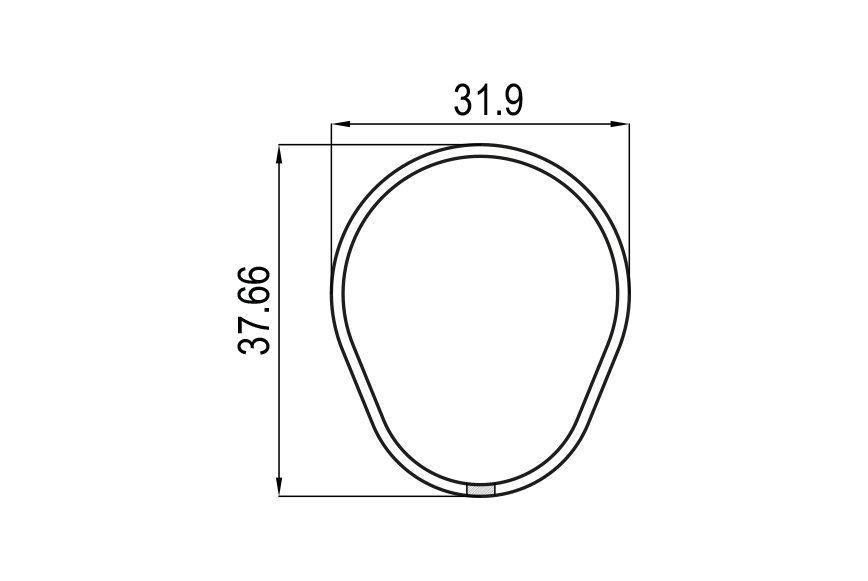

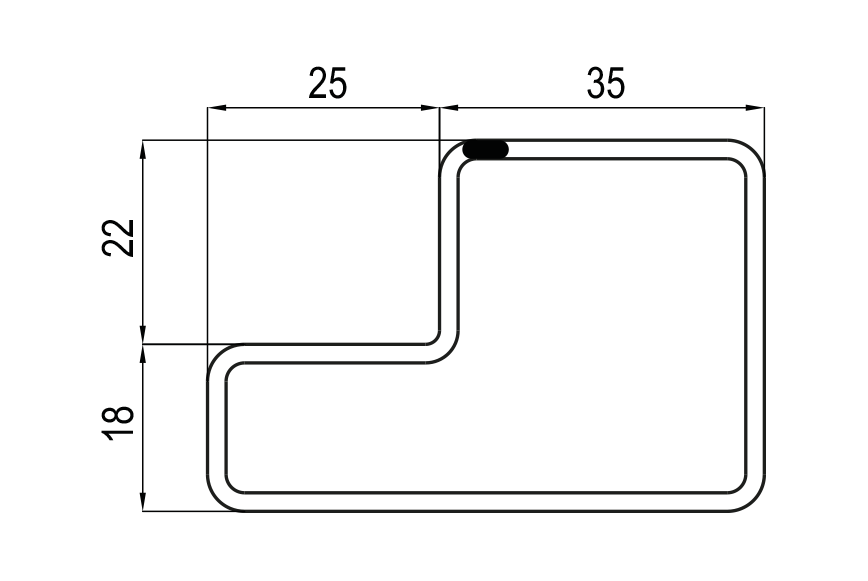

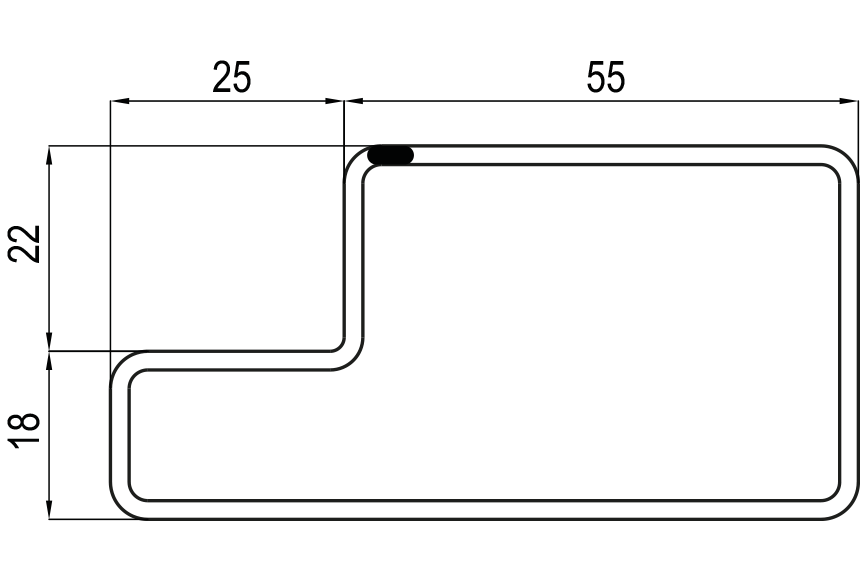

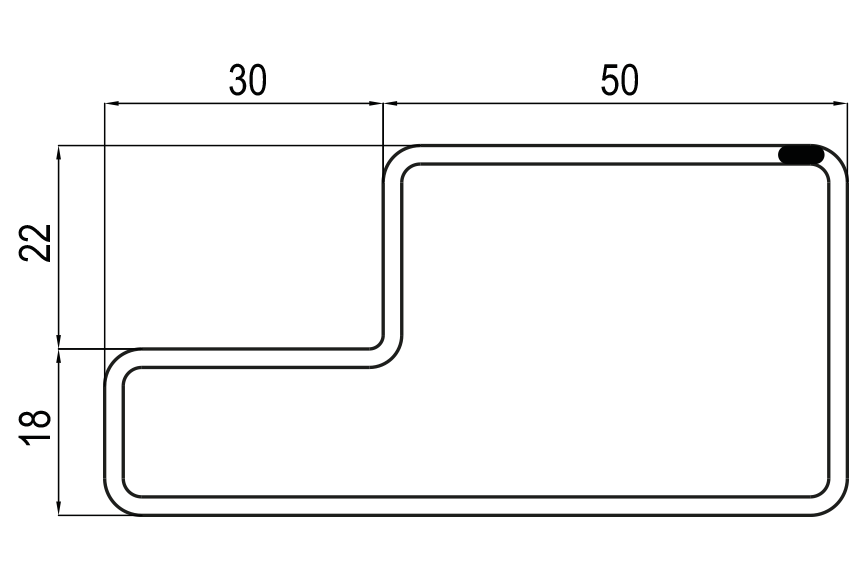

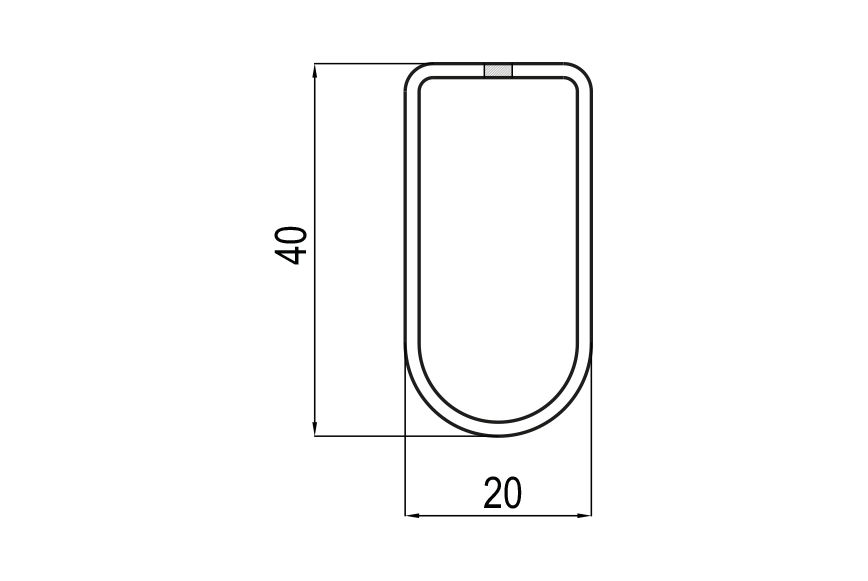

Our range includes:

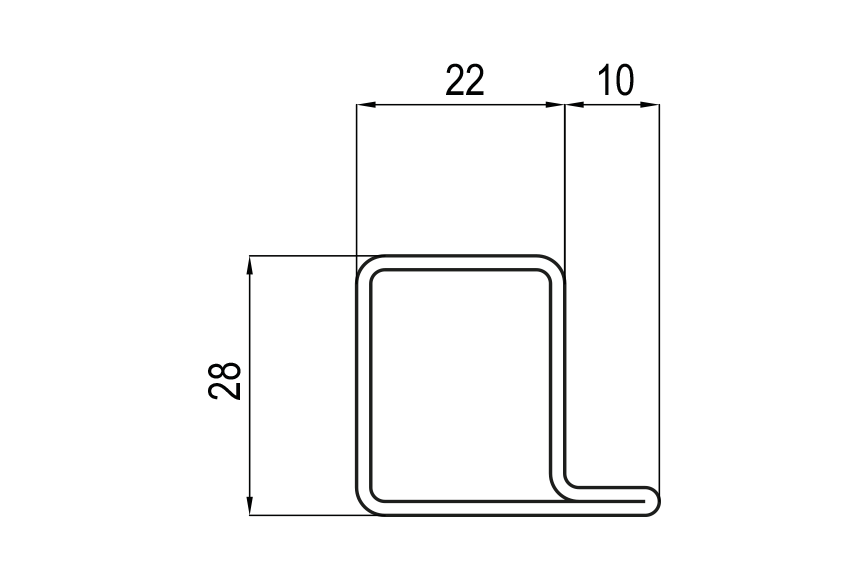

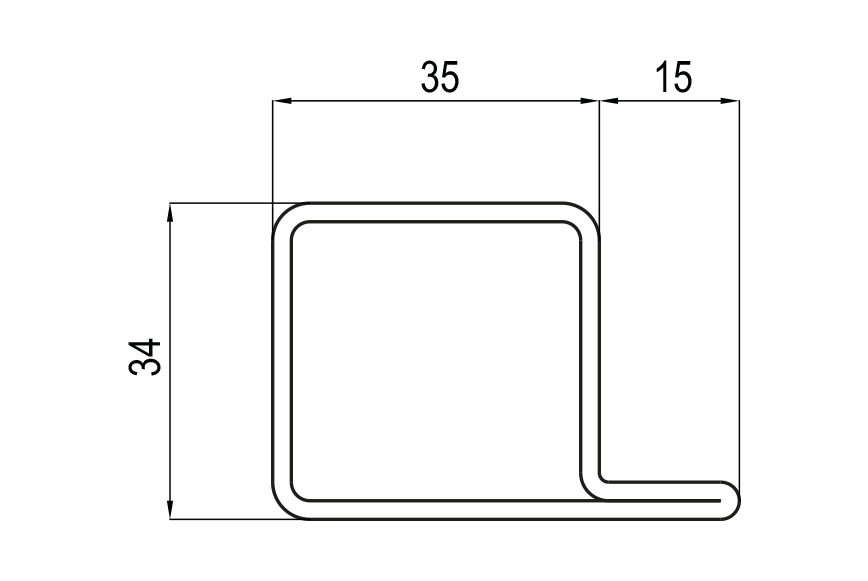

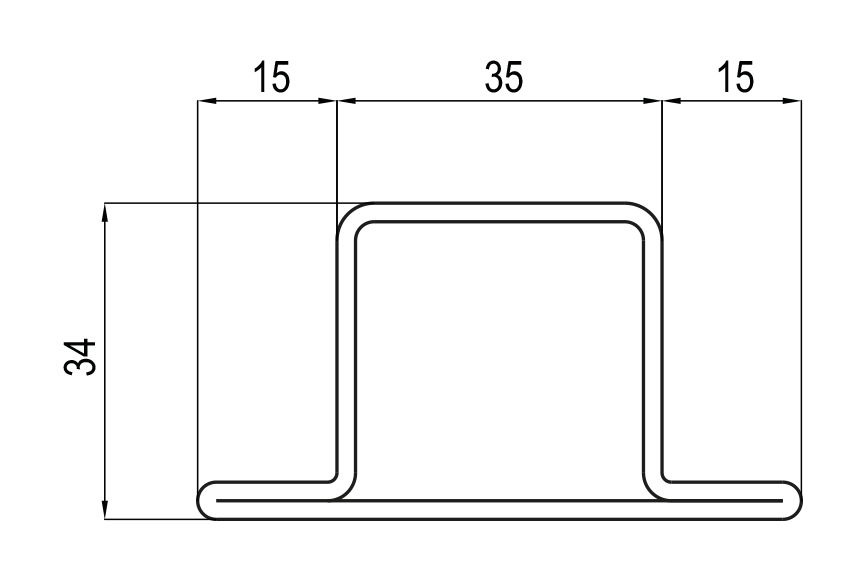

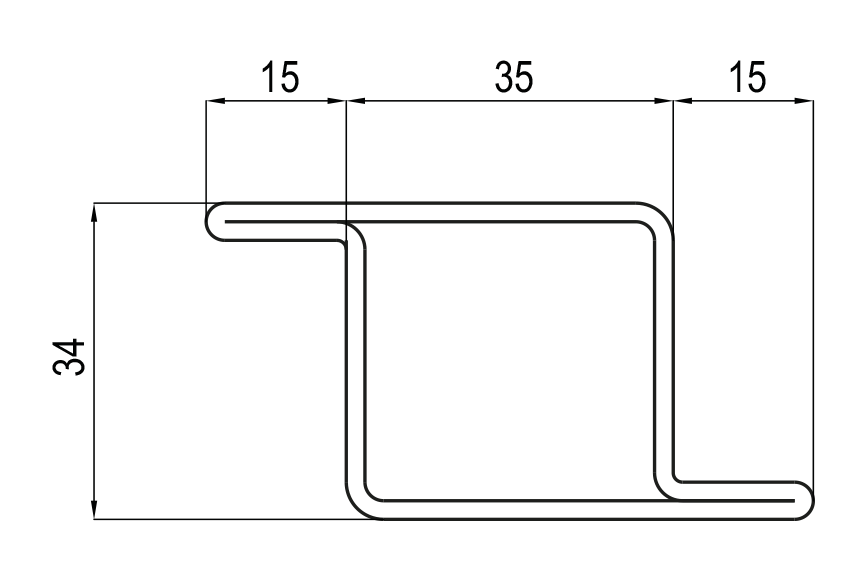

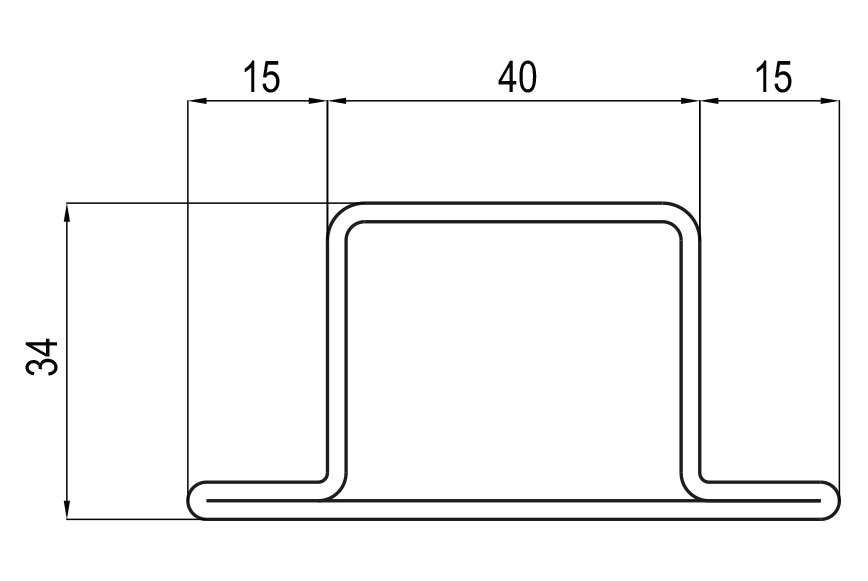

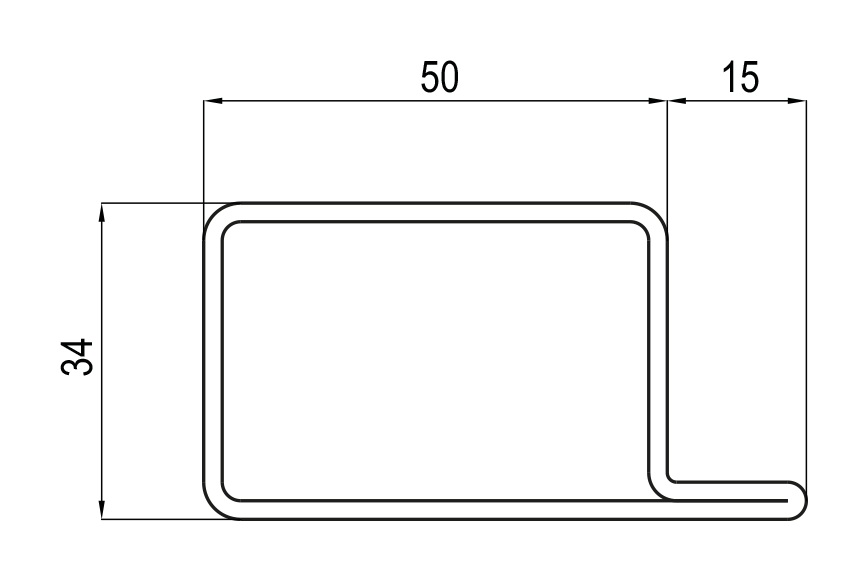

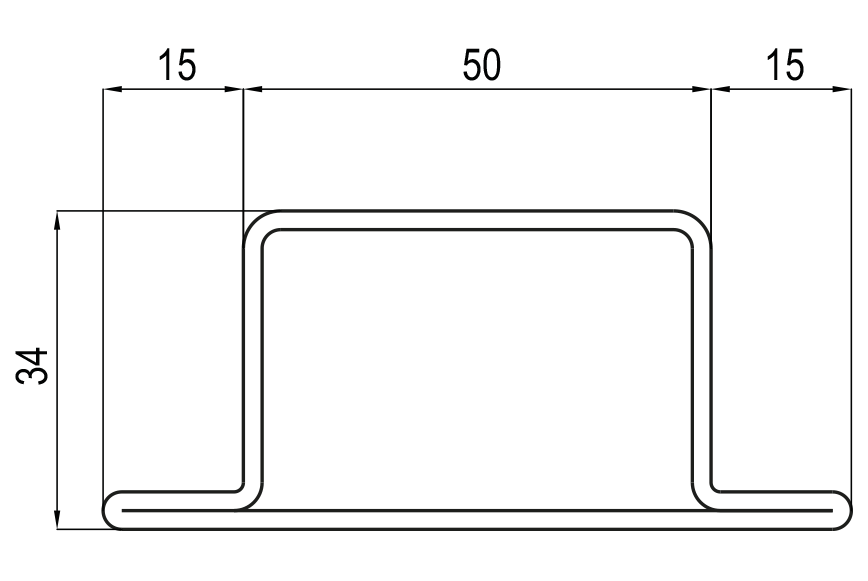

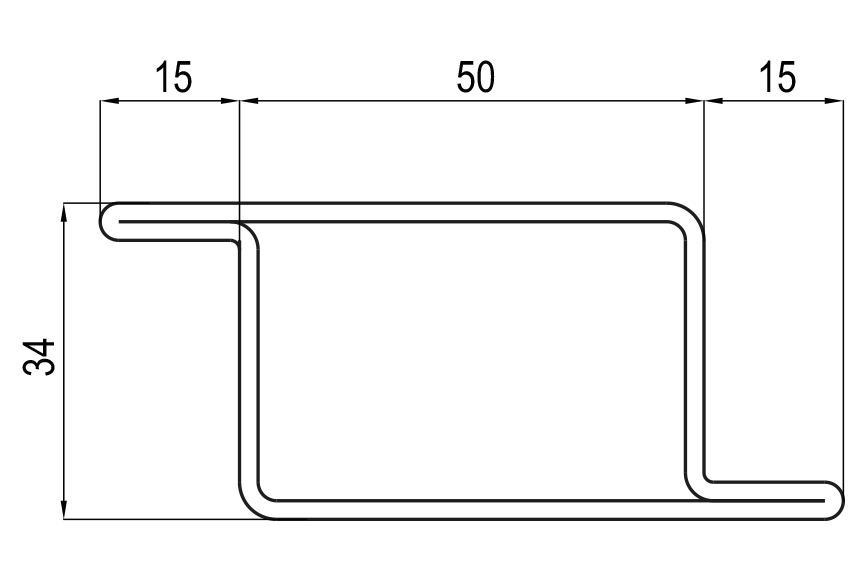

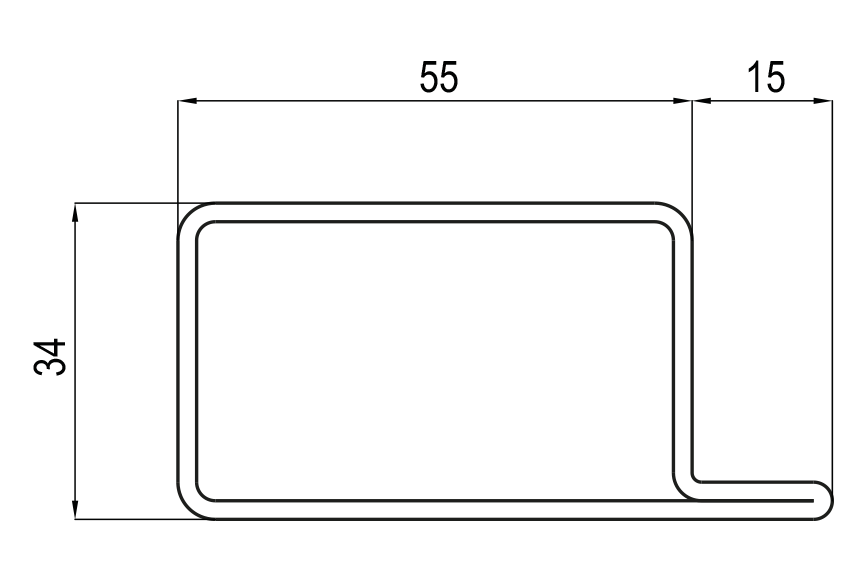

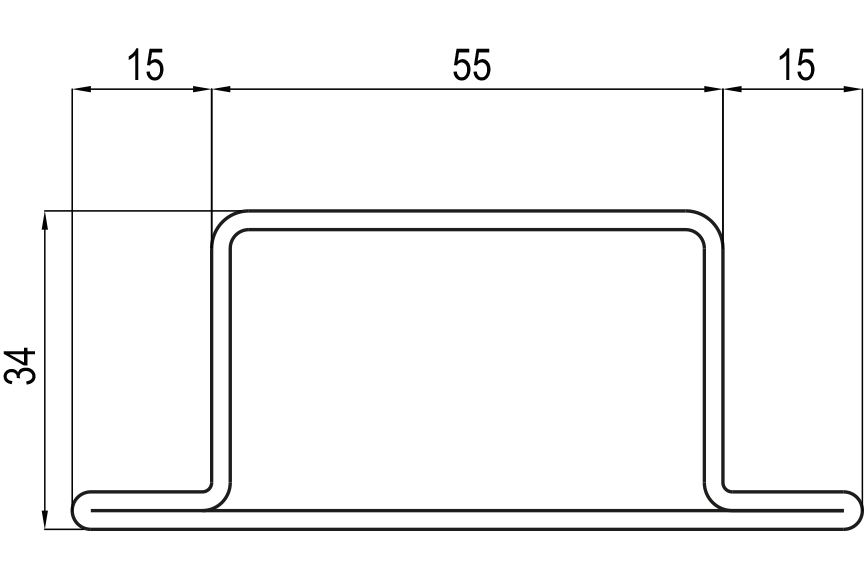

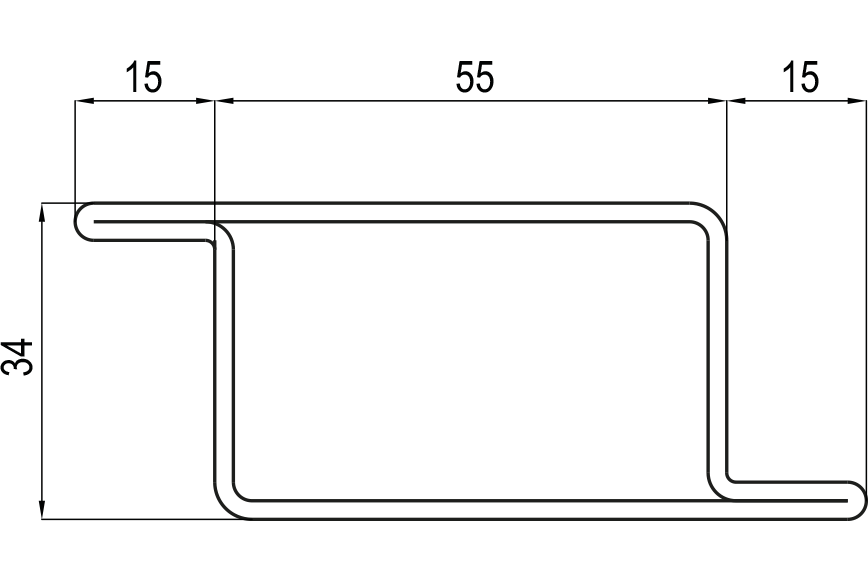

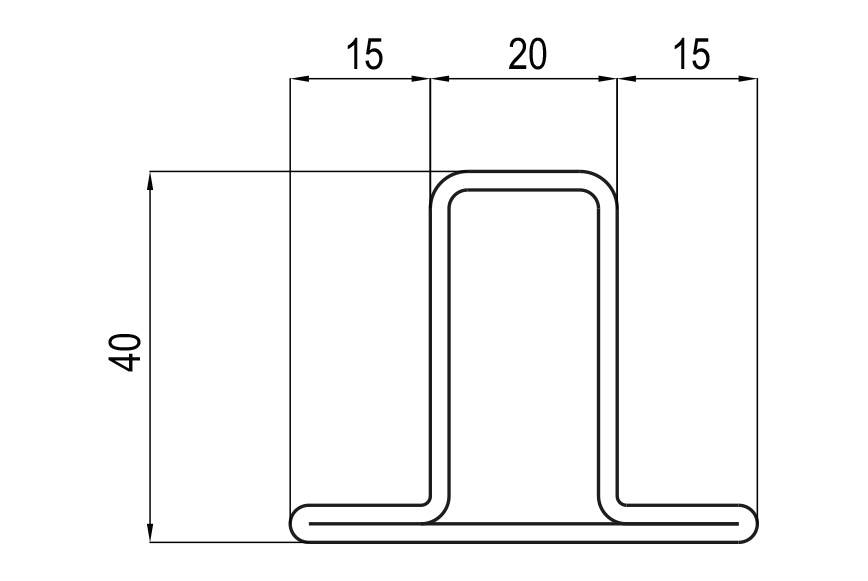

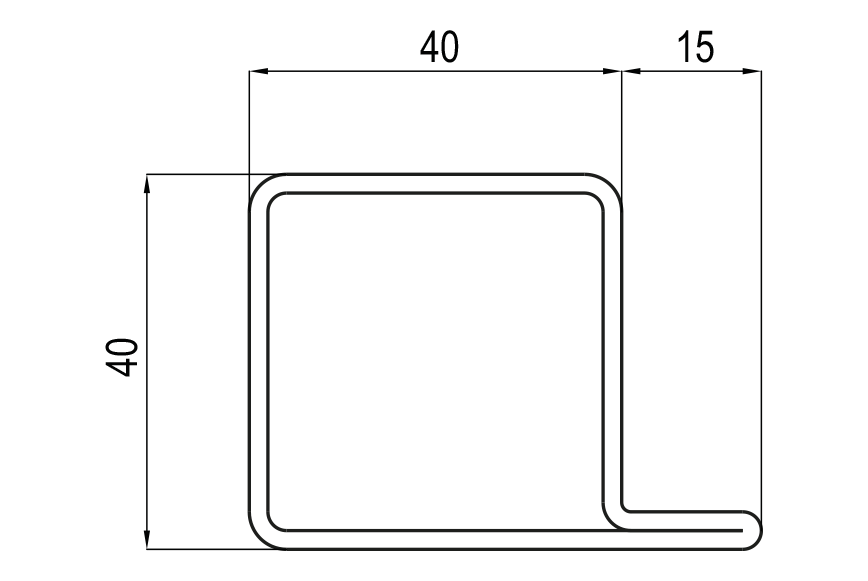

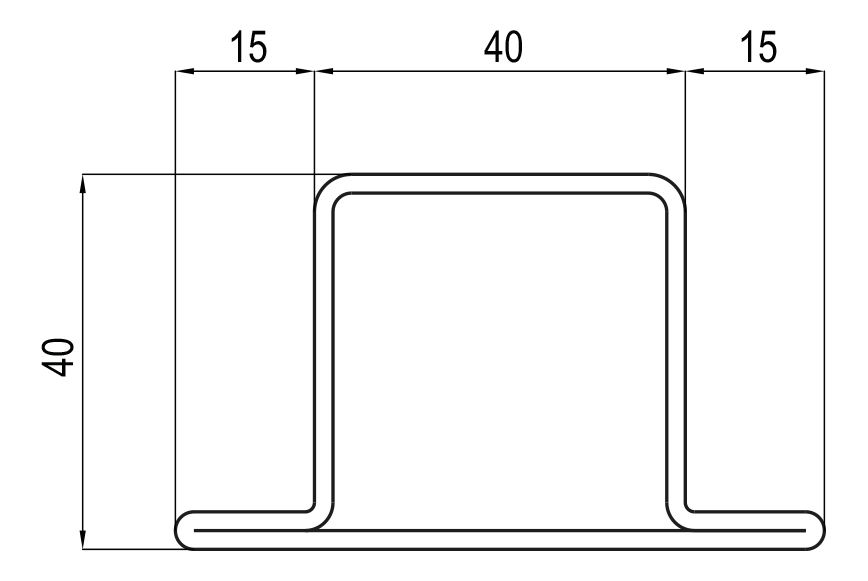

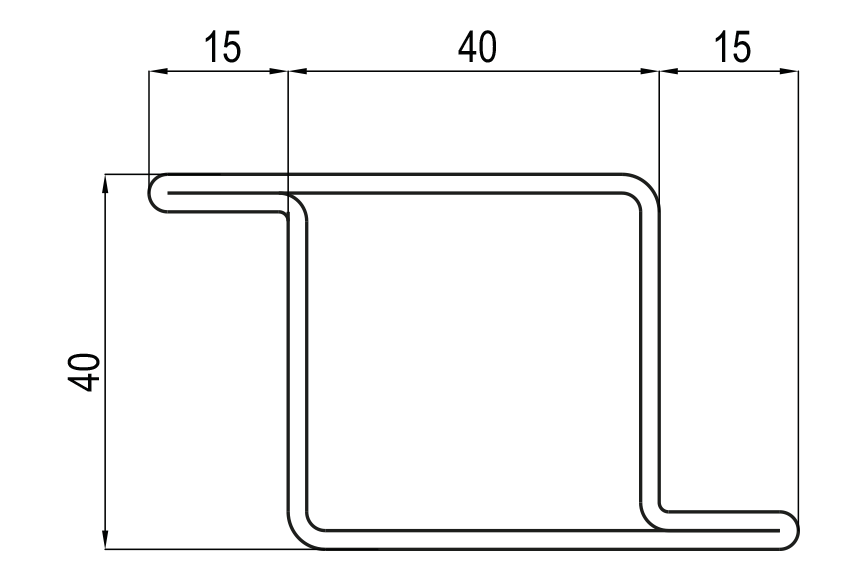

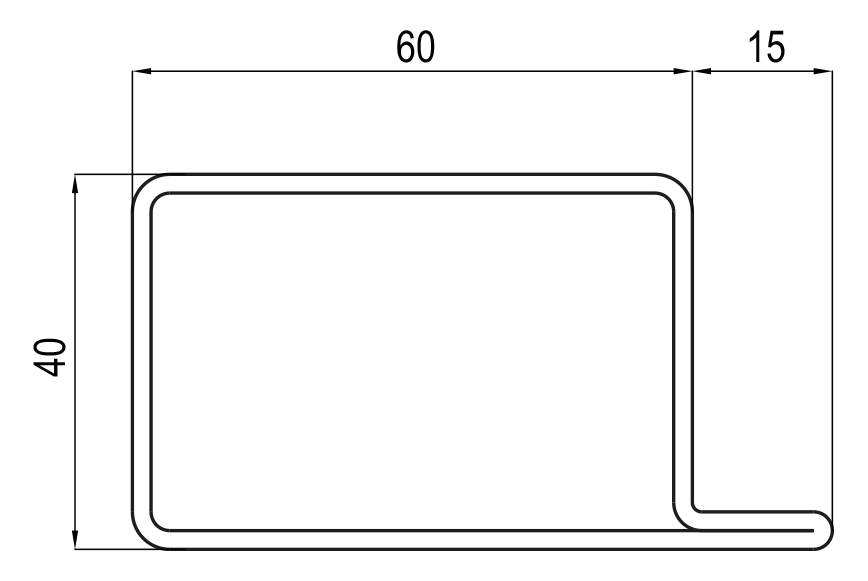

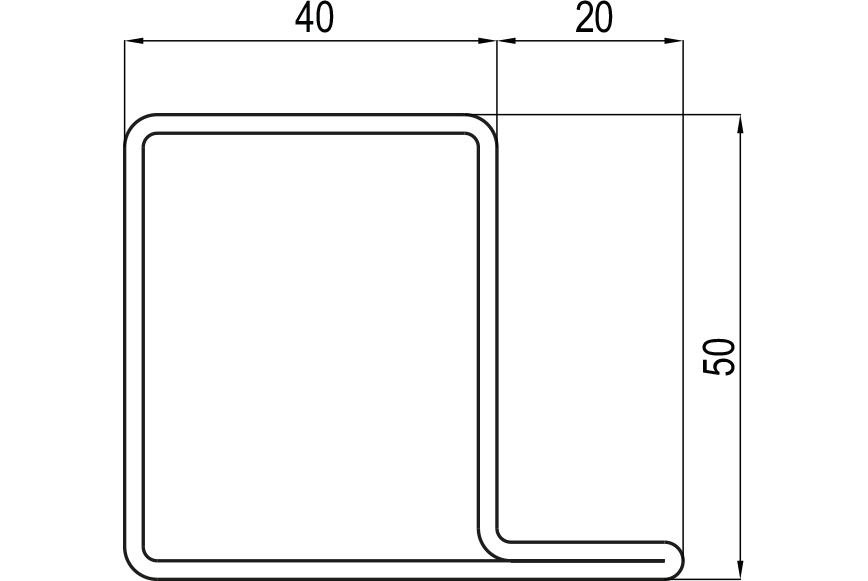

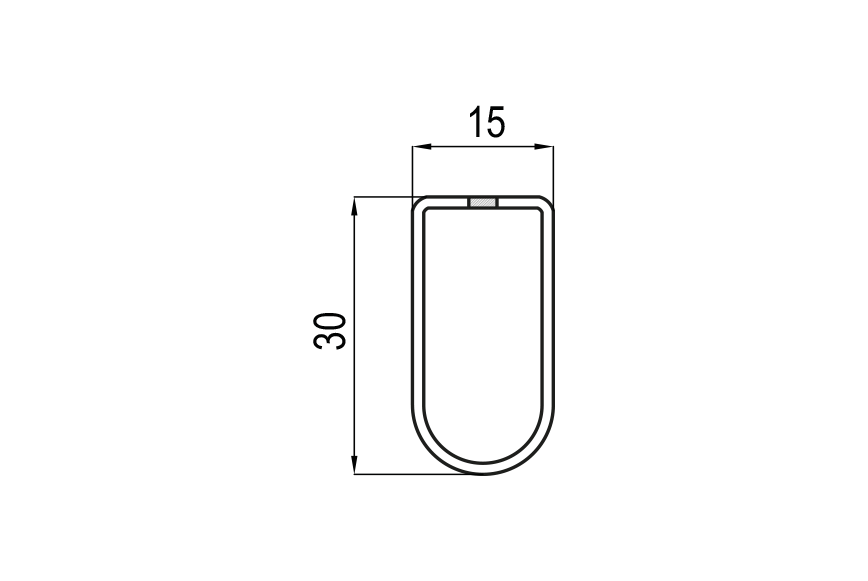

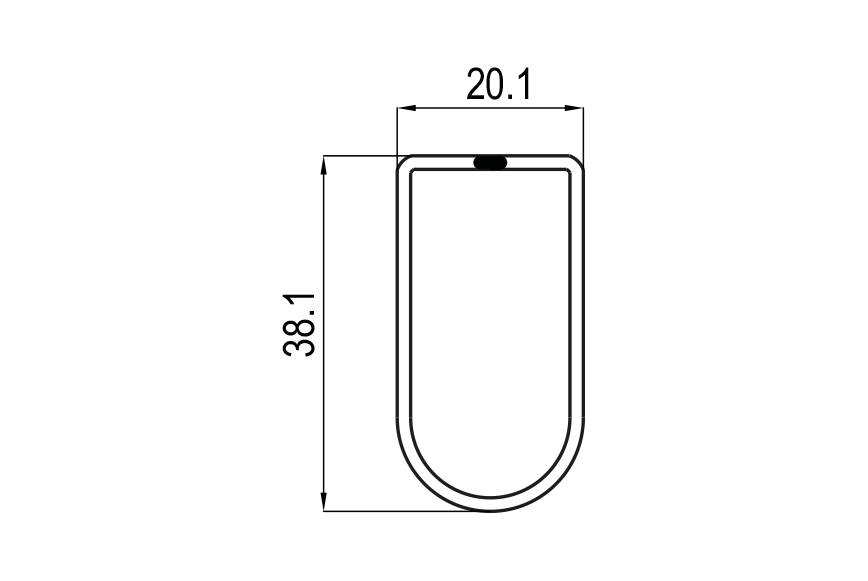

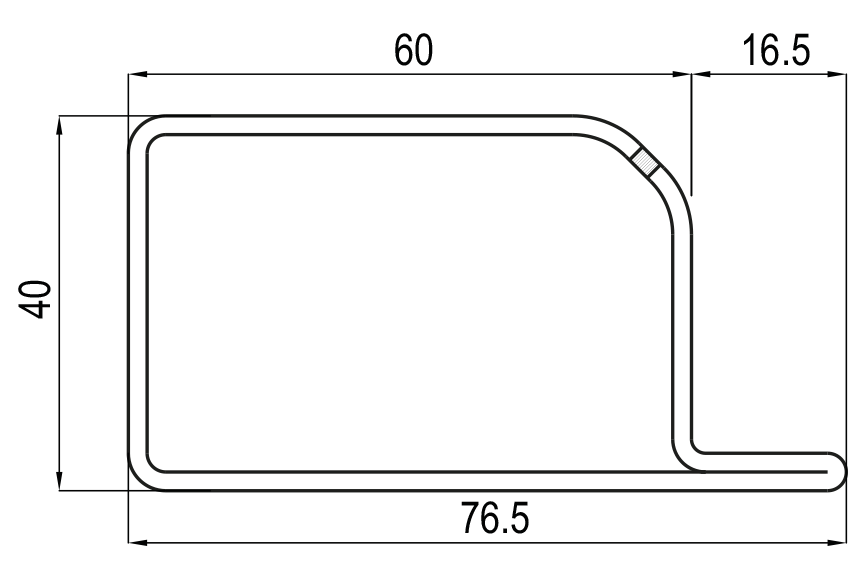

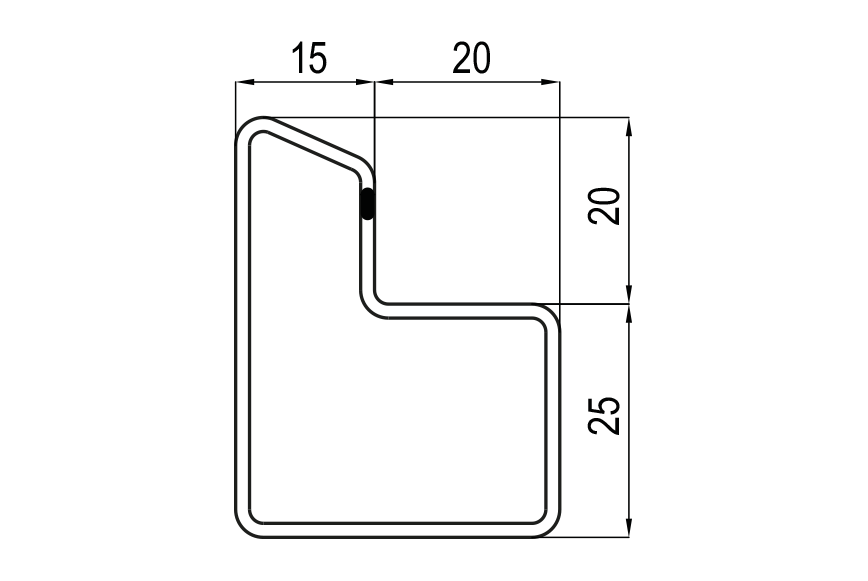

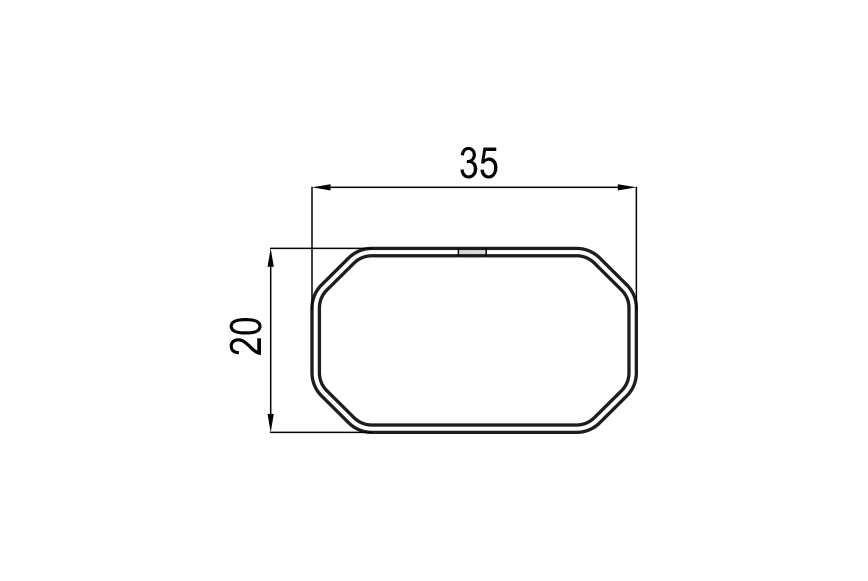

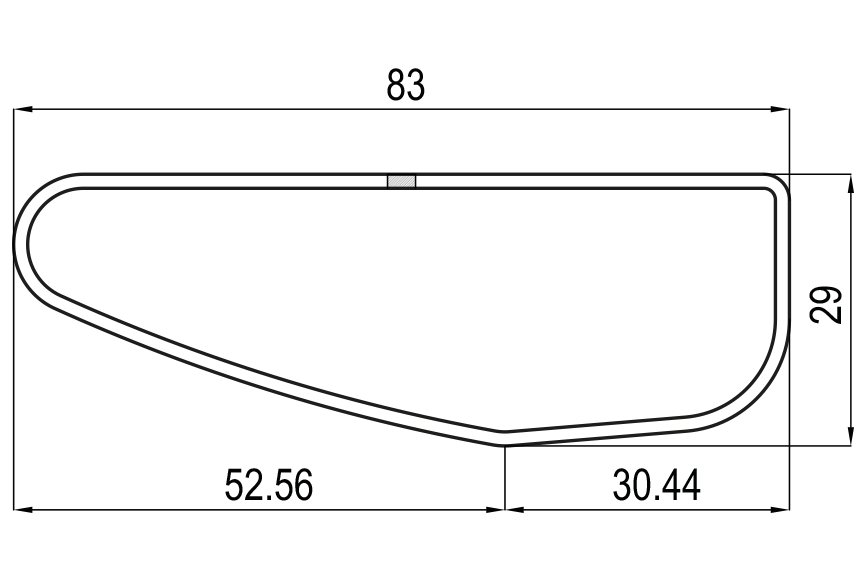

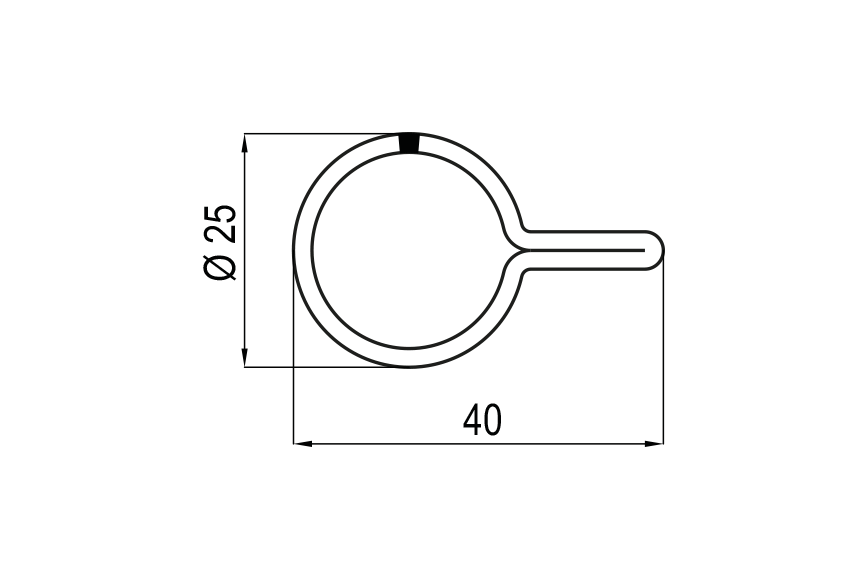

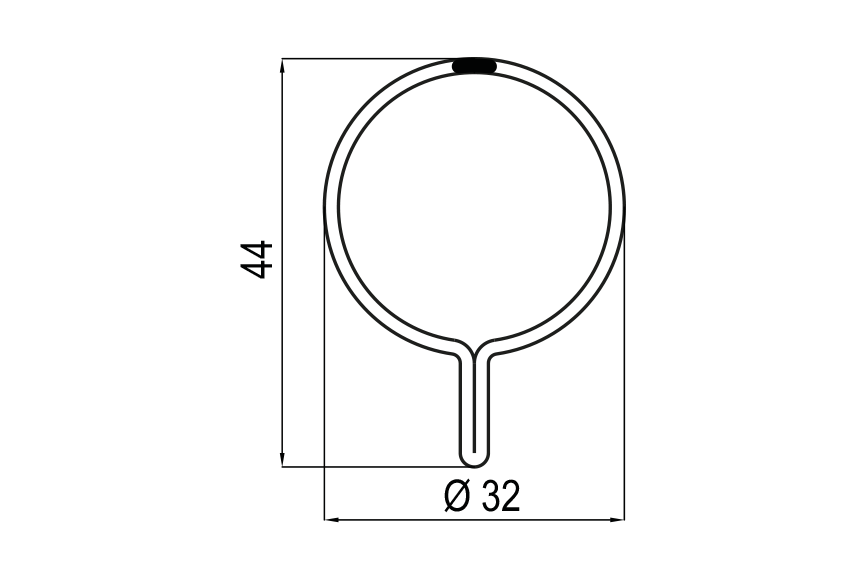

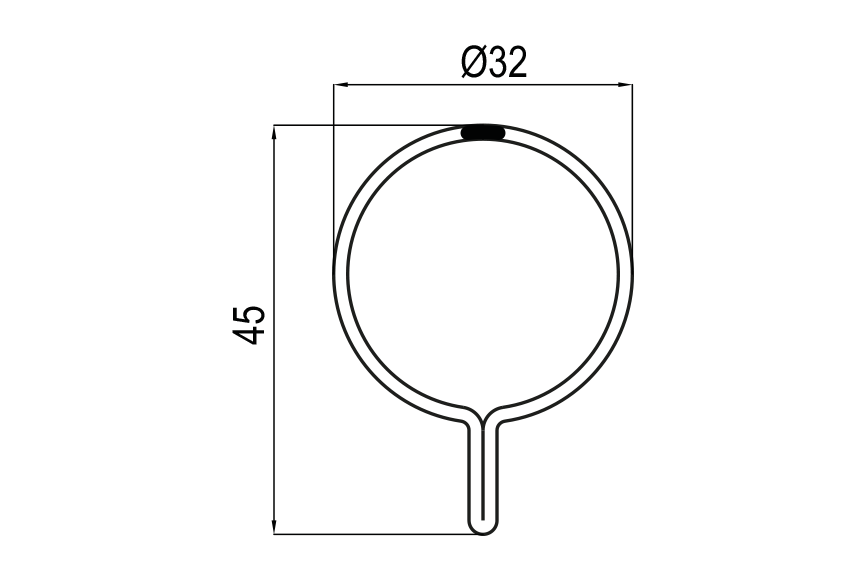

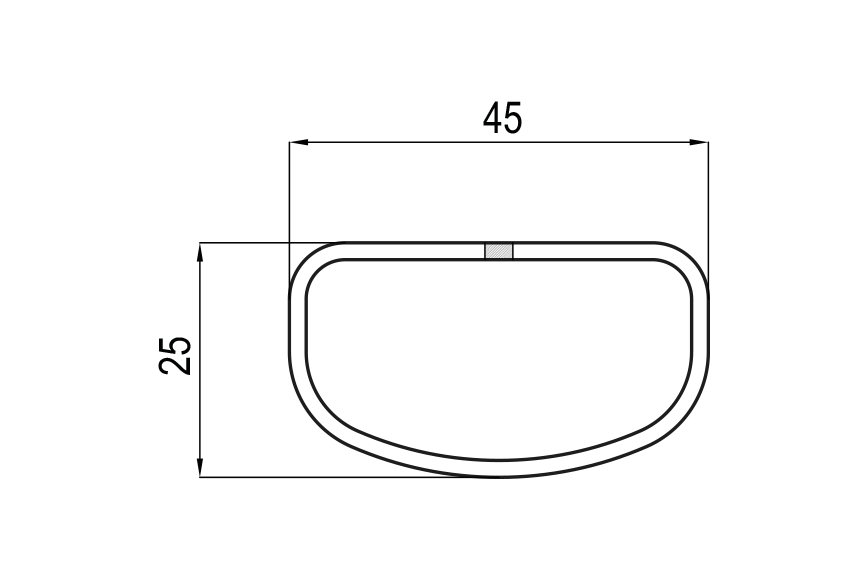

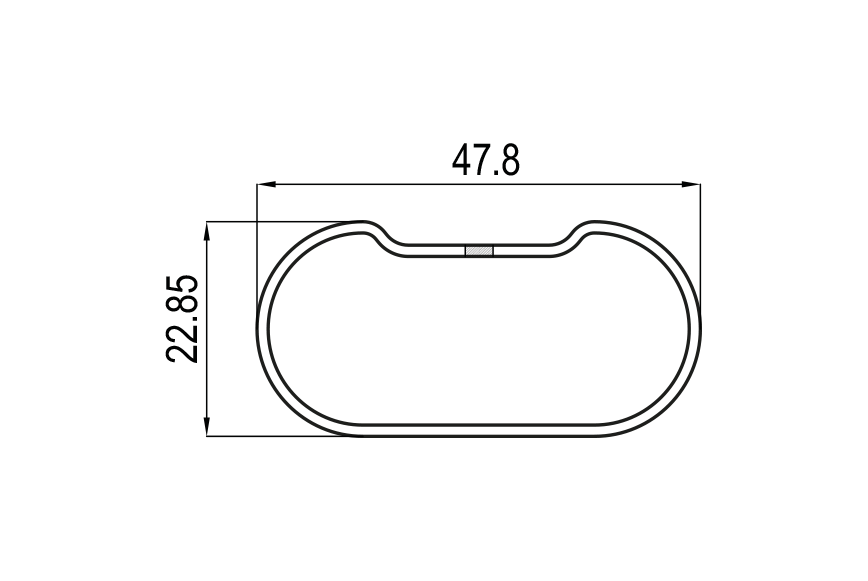

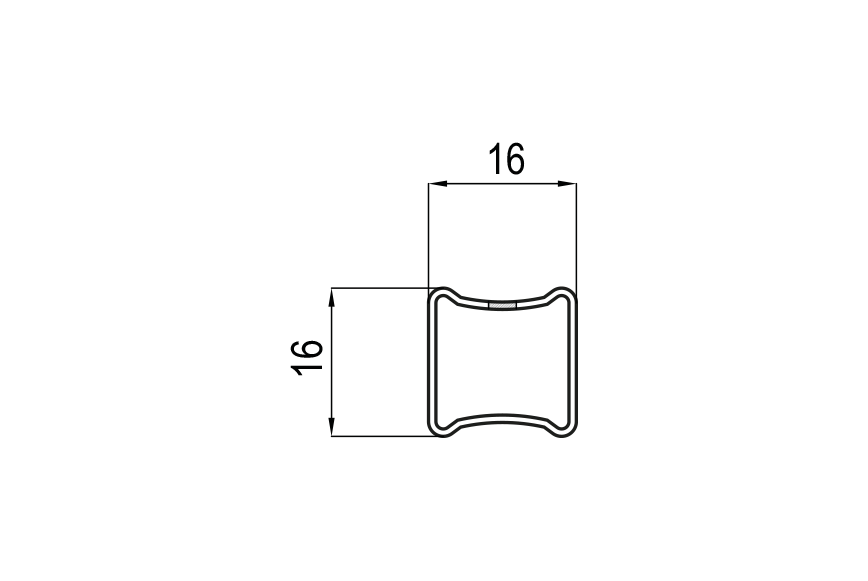

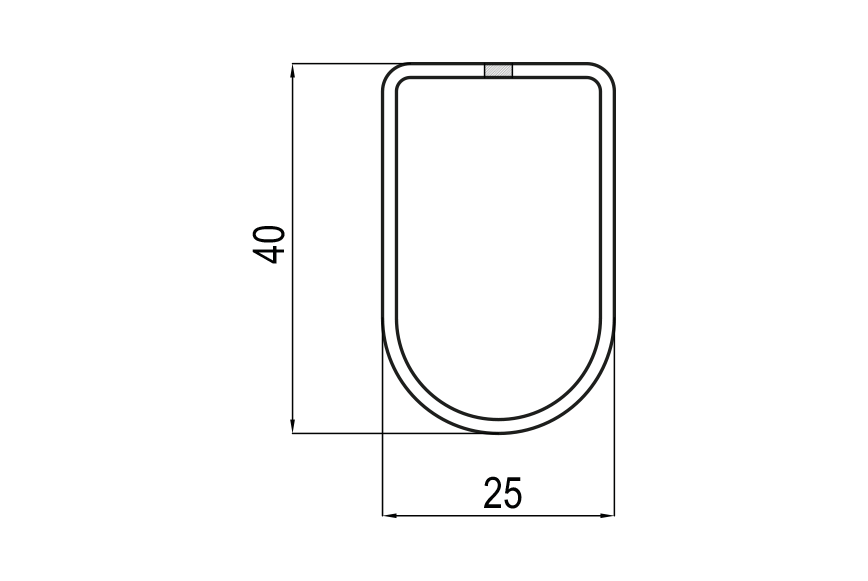

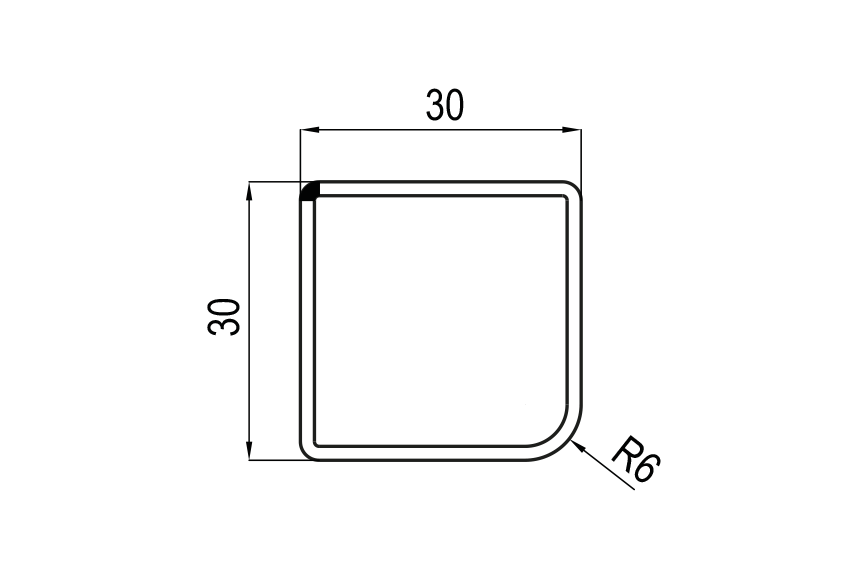

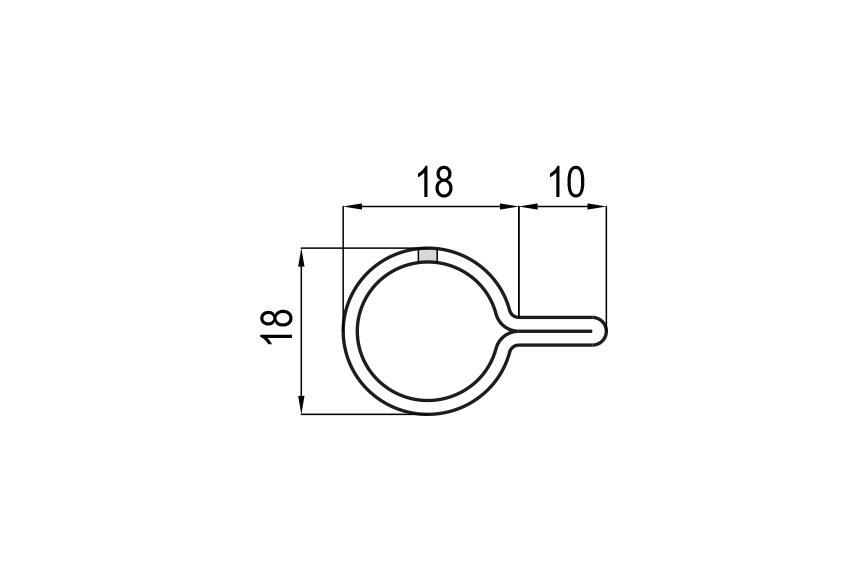

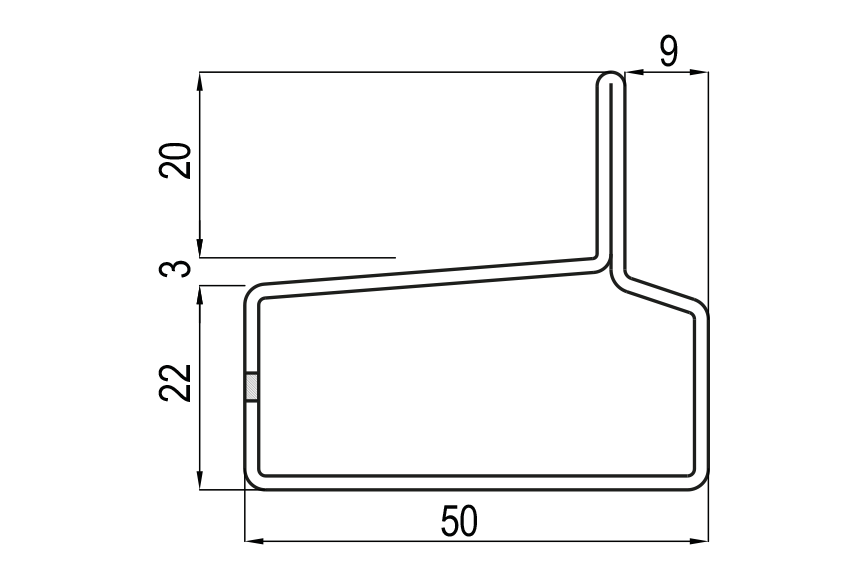

- Tubes from hot-rolled pickled strips (S2) with thicknesses from 1.4 to 3.0 mm, diameters from 10 to 76 mm and derived shapes (square, rectangular, oval, special profiles).

- Tubes from cold-rolled strips (S3) with thicknesses from 0.5 to 2.5 mm, diameters from 9.5 to 60 mm and derived shapes (square, rectangular, oval, special profiles).

- Tubes from coated strips (galvanized, zincmagnesium) (S4) with thicknesses from 0.6 to 3.0 mm, diameters from 14 to 76 mm and derived shapes (square, rectangular, oval, special profiles).

The outer welding seam can be zinc-coated.

All our production lines, with the latest technologies available on the market, enable us to manufacture the normal qualities provided by the standards:

- +Cr1 from E195 to E355

- +Cr2 from E190 to E600

In addition, in order to be in line with the qualitative developments which the automotive industry

especially demands, we have integrated our production range with tubes from Dual-Phase rolled strips (qualities up to HCT780X).

Tubes from cold-rolled strips can be manufactured using the cold re-rolled strips we produce, so that we can, in this case, guarantee surface roughness less than 0.4 microns, particularly tight thickness tolerances and “customized” mechanical characteristics.

ANCILLARY SERVICES

We can supply S2 and S3 tubes with internal welding seam removed upon our customers’ request starting from outer diameter 18 mm.

Our tubes are supplied at machine lengths from 3,000 to 13,000 mm with -0+10 mm tolerance.

Alternatively, we can supply cut to length tubes with lengths going from 150 to 3,000 mm with tolerances up to +/- 0.2 mm.

In this case the tubes may have brushed ends and can be washed.

Our tubes are supplied at machine lengths from 3,000 to 13,000 mm with -0+10 mm tolerance.

Alternatively, we can supply cut to length tubes with lengths going from 150 to 3,000 mm with tolerances up to +/- 0.2 mm.

In this case the tubes may have brushed ends and can be washed.